- Acid resistant brick & Tile

- Ceramic Random Packing

- Ceramic structured packing

- Environmental Ceramic

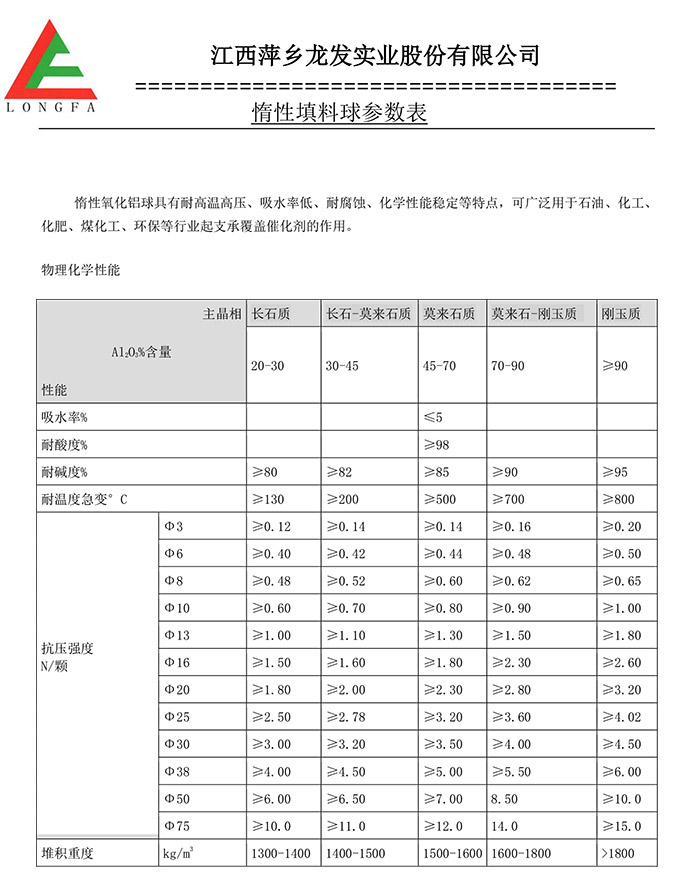

- Inert ceramic ball

- Plastic metal packing

- KP1 mortar

JiangXi PingXiang LongFa Enterprise Co., Ltd. was established in 2001, with a registered capital of 106 million RMB and an area of 400 mu. It is the President Company of "PingXiang industrial ceramics industry chamber of commerce of JiangXi province".After nearly 20 years of cont...

- Never forget history, we should strive for self-improvement. Longfa Industrial Organization watched the m...

- 2024 Honor Wall...

- Expert in Acid Resistant Brick Board Production - Record of Longfa Industrial Intelligent Manufacturing o...

- Longfa Industrial acid resistant brick intelligent digital production line has been successfully put into...

- Longfa Industrial s New Year s greeting...

JiangXi PingXiang LongFa Enterprise Co., Ltd. was established in 2001, with a registered capital of 106 million RMB and an area of 400 mu. It is the President Company of "PingXiang industrial ceramics industry chamber of commerce of JiangXi province".After nearly 20 years of cont...

- Never forget history, we should strive for self-improvement. Longfa Industrial Organization watched the m...

- 2024 Honor Wall...

- Expert in Acid Resistant Brick Board Production - Record of Longfa Industrial Intelligent Manufacturing o...

- Longfa Industrial acid resistant brick intelligent digital production line has been successfully put into...

- Longfa Industrial s New Year s greeting...

JiangXi PingXiang LongFa Enterprise Co., Ltd. was established in 2001, with a registered capital of 106 million RMB and an area of 400 mu. It is the President Company of "PingXiang industrial ceramics industry chamber of commerce of JiangXi province".After nearly 20 years of cont...

- Never forget history, we should strive for self-improvement. Longfa Industrial Organization watched the m...

- 2024 Honor Wall...

- Expert in Acid Resistant Brick Board Production - Record of Longfa Industrial Intelligent Manufacturing o...

- Longfa Industrial acid resistant brick intelligent digital production line has been successfully put into...

- Longfa Industrial s New Year s greeting...

- Company Introduction

- Chairman speech

- Organizational structure

- Development histroy

- Enterprise culture

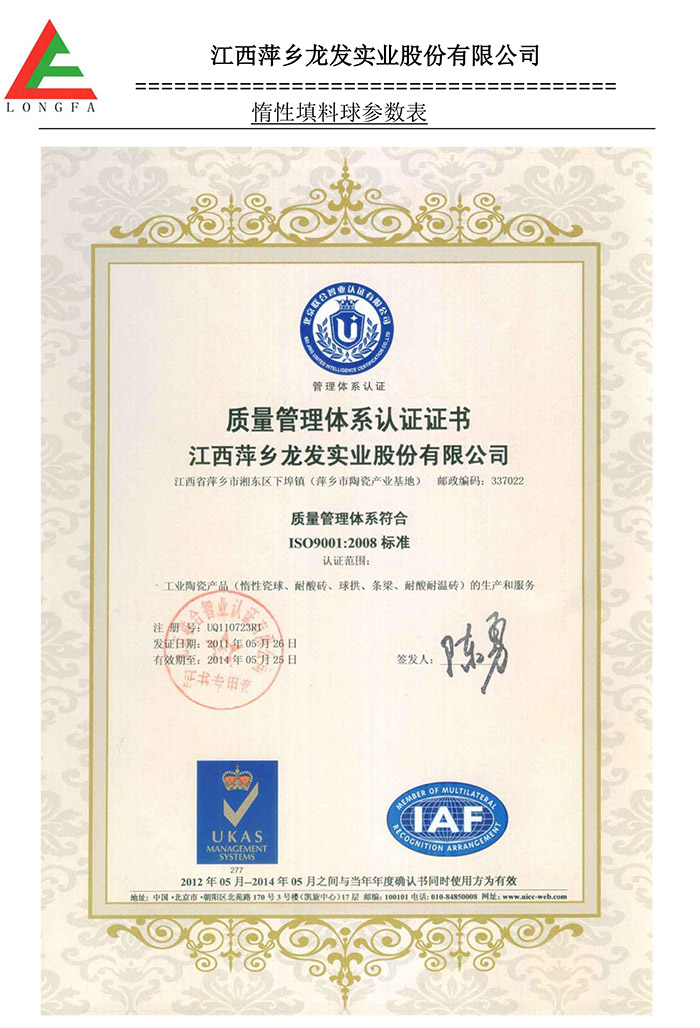

- Enterprise qualification

- Enterprise honor

- Factory environment

- R&D center

- Social Responsibility

JiangXi PingXiang LongFa Enterprise Co., Ltd. was established in 2001, with a registered capital of 106 million RMB and an area of 400 mu. It is the President Company of "PingXiang industrial ceramics industry chamber of commerce of JiangXi province".After nearly 20 years of cont...

- Never forget history, we should strive for self-improvement. Longfa Industrial Organization watched the m...

- 2024 Honor Wall...

- Expert in Acid Resistant Brick Board Production - Record of Longfa Industrial Intelligent Manufacturing o...

- Longfa Industrial acid resistant brick intelligent digital production line has been successfully put into...

- Longfa Industrial s New Year s greeting...